Green Chemicals, State of the Industry 2023

Green chemistry is a design methodology that aims to create chemical compounds with minimal negative impacts on the health of both the environmental and human populations. In other words, green chemistry solutions are attempts to create chemicals needed for various industries but in a way that promotes sustainability and environmental safety first. The green chemicals and materials market is already a $101B+ global market and projected to grow at 9.5% CAGR to reach $229B by 2030, and this industry is poised to become a key element of the climate solution in both the breadth of production methods and contexts it can cover.

Green chemicals are the compounds produced from adhering to the principles of green chemistry.

Many of the useful compounds upon which modern society relies – anything from plastics, to rubber, to fertilizers, medicines, and pesticides – currently come from fossil fuels. In a typical synthetic process, the chemical and adjacent industries first take oil, natural gas, or coal and use a series of chemical reactions to create the end products. Although these processes allow these compounds to be made on a scale of hundreds of millions of tons per year to support modern society, their production generates both hazardous byproducts and greenhouse gasses. Therefore, the goal of green chemistry involves creating these same chemicals in a more sustainable manner or, alternatively, “greener” chemicals to replace those made from fossil fuels. The products of green chemistry can be called green chemicals.

Within the context of chemical synthesis, “more sustainable” can mean several things; indeed, 12 specific points underlie green chemistry, as shown above. Ultimately, these all revolve around protecting the health of humans and the environment while still being realistic for industrial-scale chemical reactors. Accordingly, working under these principles, the chemical industry has seen considerable innovation resulting in reduced GHG emissions, minimized waste, and developing alternative reactions that are more efficient.

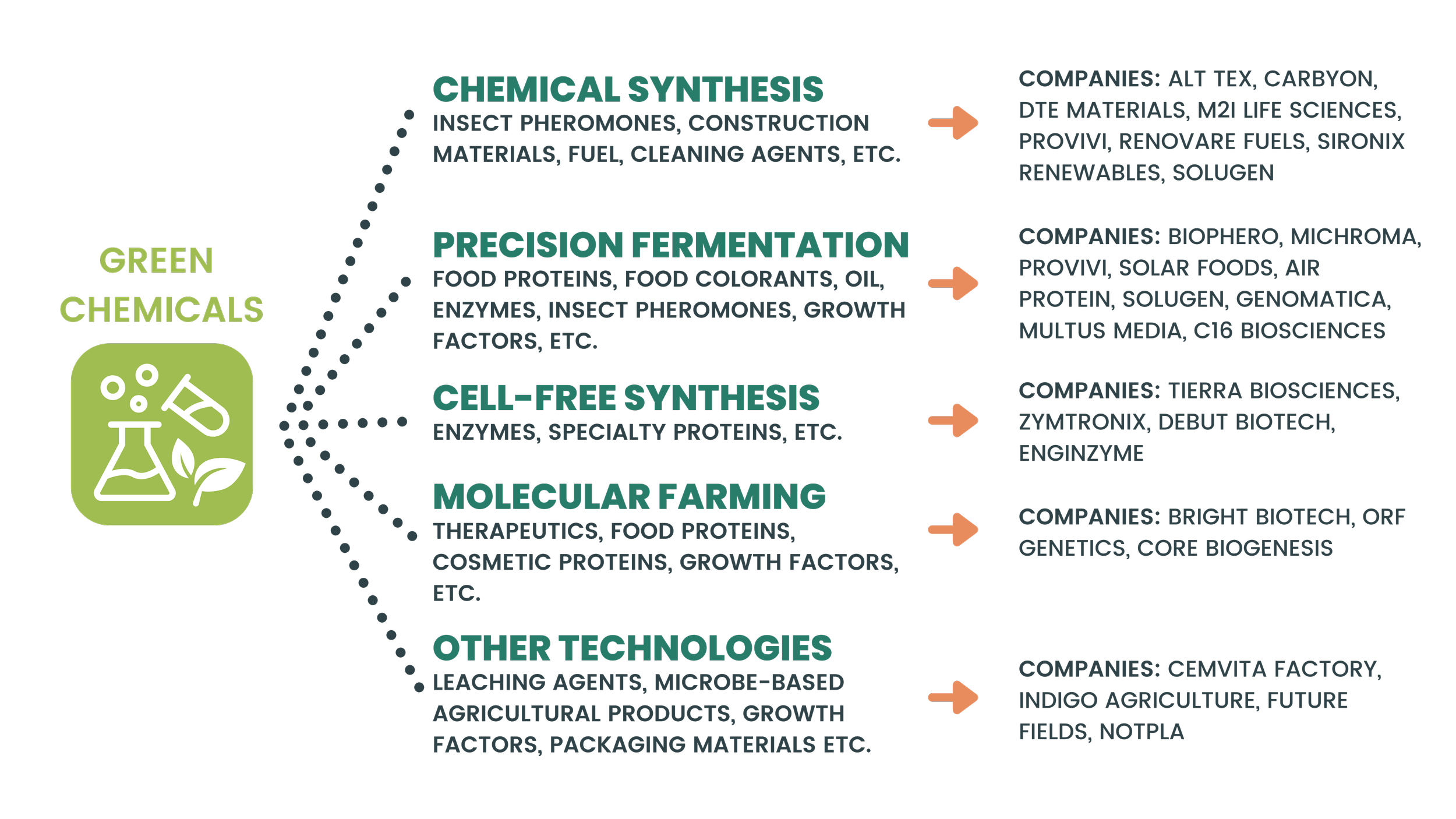

Green chemistry, therefore encompasses several technologies that fulfill the aforementioned principles and objectives. In 2023, however, the technologies of precision fermentation, cell-free synthesis, and molecular farming are of special note in showing promise to produce a variety of green chemical compounds across virtually all industries.

Precision fermentation, cell-free synthesis, and molecular farming make use of living systems to conduct green chemistry.

A longstanding method to produce chemicals in a sustainable manner is precision fermentation, a synthesis route that builds upon the disciplines of metabolic and genetic engineering. Precision fermentation uses an engineered microorganism, such as yeast, to produce a desirable molecule from the microorganism’s consumption and metabolic conversion of a food source, like sugar. The molecule is either made within the organism or is secreted, and it can be simple, such as Genomatica’s butanediols, or more complex, such as the protein leghemoglobin used in the Impossible Burger. In either case, the end product can be utilized directly or used in subsequent chemical reactions to make other products. Of note, enzymes produced via precision fermentation can be used as either end products, such as amylases in bread, or as catalysts in place of traditional chemical synthesis reaction steps. In the context of green chemistry, precision fermentation enables the use of renewable feedstocks (as opposed to fossil fuels) like sugars or even waste products as inputs into the process. Because microbes serve as living “cell factories,” precision fermentation is carried out at neutral reaction conditions, moderate temperatures and pressures, and in nontoxic solvents.

Cell-free synthesis is another green chemistry solution that employs cell extracts or purified enzymes in the manufacturing process. Whereas precision fermentation utilizes whole and living microbial cells to carry out the reactions, cell-free synthesis uses cellular extracts from inactivated or ruptured cells to access the enzymes that carry out the intended conversion process. Because living cells are not required, chemical compounds that are usually toxic to live cells can be produced in high quantities using this method. Solugen uses enzymatic synthesis and advanced bioreactor design to produce a variety of commodity and specialty chemicals, such as hydrogen peroxide for water treatment applications. Founded in 2011, they have closed a $200M series D round in late 2022 with most of the funds to be used for buildout of a large-scale bioreactor facility.

Finally, molecular farming is yet another method by which useful compounds can be produced. Similar to precision fermentation, molecular farming employs genetically engineered plants to produce a molecule of interest. The plant is then grown in the field, harvested, and the desired product is extracted and purified from the plant material. A number of valuable yet difficult-to-produce pharmaceuticals and proteins are made using this method. This is because certain proteins need to be modified with specific sugars (e.g. glycosylated) in order to be active, and this process can’t be carried out in many microbial hosts used for precision fermentation (they lack the cellular components to do so correctly). Another advantage of this method is that the waste from processing the starting plant material can potentially be reused, creating a circular, rather than linear value chain; this is yet another principle of green chemistry. Bright Biotech, based in the UK, uses plants to make high valued proteins for life science companies and recently raised a $3.2M seed round to scale its operations.

Green chemistry is a focus of large established international firms as well as start-ups across a myriad of industries.

Over the last five years, dozens of precision fermentation, cell-free synthesis, and molecular farming companies have emerged to address the growing market demand for greener chemicals across the industries of food, textile, packaging, and others. This is apparent from the dollar amounts invested at both the government and private capital being invested. The tables below summarize some of the most recent innovations in this field.

Nevertheless, the story of green chemistry innovation is not limited to the above technologies and companies; green chemicals produced from green chemistry approaches can exist for several different contexts and several different production methods. Estée Lauder Companies, a global leader in cosmetic and personal care products, has a green chemistry approach to product development. Pfizer is emphasizing green chemistry and alternate synthetic routes to its drugs as part of its net-zero 2040 commitment. Sironix Renewables is a startup founded in 2016 now based in Seattle, WA that’s developing plant-based cleaning agents for laundry detergents and other household products. Another startup, ALT TEX, based in Canada, makes bioplastics for the textile industry from food waste. The space for innovation in creating either green chemistry synthetic routes or green chemicals themselves continues to be broad and open for established companies and start-ups alike.

Finally, there are also companies that use green chemistry to create green chemicals. For example, michroma, a startup based in Argentina, uses precision fermentation to make red food coloring. Not only is precision fermentation a green chemistry, but michroma’s food dye itself is a green chemical that can replace the fossil-fuel-derived red food coloring currently used in the food and cosmetics industries. Plastic alternatives are another example, such as those developed by Notpla, a startup founded in 2014 that transforms seaweed into a variety of biodegradable food containers. As green chemistry technologies develop and improve, more companies that use these guidelines to create green chemicals and products may appear.

Green chemistry approaches combined with a deep understanding of ecology can lead to unexpected innovations in environmental sustainability.

Nevertheless, simply replacing petroleum-based processes with synthetic routes that use living systems to create green chemicals is not the only source of innovation for green chemistry. One area where green chemistry has made significant progress is in the production of pheromones.

Pheromones, the airborne molecules animals use to communicate, may be considered a green chemical (specifically, a biopesticide) when used to replace pesticides in agricultural applications, owing to their low effective dose and high target specificity (resulting in a lower ecological impact). The production of pheromones has traditionally involved the use of expensive and complex synthetic routes and harsh chemicals and solvents in order to make these molecules biologically active. However, researchers and companies have been working to develop new, green-chemistry-based methods for producing pheromones, sometimes by utilizing precision fermentation.

Two large companies, BASF and Shin-Etsu have invested heavily in pheromone biopesticides, although a few startups have emerged in recent years, such as Provivi based in California, and m2i based in Europe. Provivi was awarded the 2022 EPA Green Chemistry Challenge Award for their pheromone product used to control the fall armyworm; they are trialing this compound in corn fields in Mexico and also on higher value crops such as grapes. The future of combining deep ecological knowledge with green chemistry and green chemical solutions makes the global industry of biopesticides and broader biocontrol a market to watch. Indeed, this market is projected to grow at over 15% per year to reach $13B+ by 2027.

Green chemistry solutions and the production of green chemicals will remain an active area of research and development even without market replacement.

While green chemistry holds enormous potential in reducing our dependence on fossil fuels, much development is still required to compete on a cost basis with traditional chemical manufacturing. Scaling is a huge issue, and in fact worldwide, there is only about 61M liters of fermentation capacity available for precision fermentation companies. This is orders of magnitude lower than traditional chemical reactors. Resources must be allocated towards increasing bioreactor capacity if precision fermentation is to compete with chemical synthesis and become a large-scale solution.

Even so, precision fermentation and other green chemical approaches may not need to compete directly with conventional chemical synthesis in order for the green chemistry industry to thrive. Instead, efforts can be made to improve upon existing chemical synthesis methods through using renewable energy sources, alternative starting compounds, engineering new or more efficient reusable catalysts and enzymes, or even identifying shorter or more energy efficient reaction methods. By combining both chemical and bioengineering research, green chemicals – and green chemistry – may eventually become the status quo of the chemical and related industries.

Written by Yekaterina Tarasova, Helikon Associate

Edited by Jeremiah Johnston

Charts by Diana Garibay, Helikon Associate

Schedule a call to learn more

Helikon Consulting strives for accuracy and completeness in our reports. If we have presented information incorrectly or unintentionally omitted relevant details, please let us know by submitting a request for updates using this form.