Bio-based Textiles, State of the Industry 2023

Bio-based textiles are the leathers, wools, silks, and down made from bacteria, fungi, and plants rather than their typical animal source. Through a combination of biomimicry and knowledge of the biological structures and composition of the animal-derived materials, startups in the space work to experiment with new bioprocesses and different organisms and material streams to create these textiles in various ways, while established clothing and automotive companies look to integrate these new materials into their current production processes. The shift in the industry is driven by consumer desire for materials that reflect and promote environmental sustainability, something that remains both a concern and an open question for the emerging bio-based textile industry as a whole.

Understanding the structure and function of the animal-derived materials at a fundamental level allows bio-based textiles to approximate animal-derived material properties.

What unites bio-based textiles as a category is that some material — whether a macroscale structure or polymer — is made by a living organism. As such, the bio-based textiles with which consumers and textile workers are most familiar – leather, fur, silk, wool, down, and exotic skins (but also cotton and linen, technically) – all derive from something that was once alive. In other words, during an organism’s life, carbon (in the form of food) was consumed, and turned into fibers that would become the skin, hair, feathers, or protein tendrils useful for the animal’s survival. With the advent of modern polymer chemistry, and an understanding of how the animal-derived materials create their properties, researchers could develop material mimics using carbon-rich petrochemicals as a starter: polyurethane for leather; polyester for silk; acrylic for wool. Although these materials were cheaper to consumers and could be created more uniformly and efficiently, they were still – and remain – fossil-fuel derived, a non-renewable and environmentally damaging carbon source.

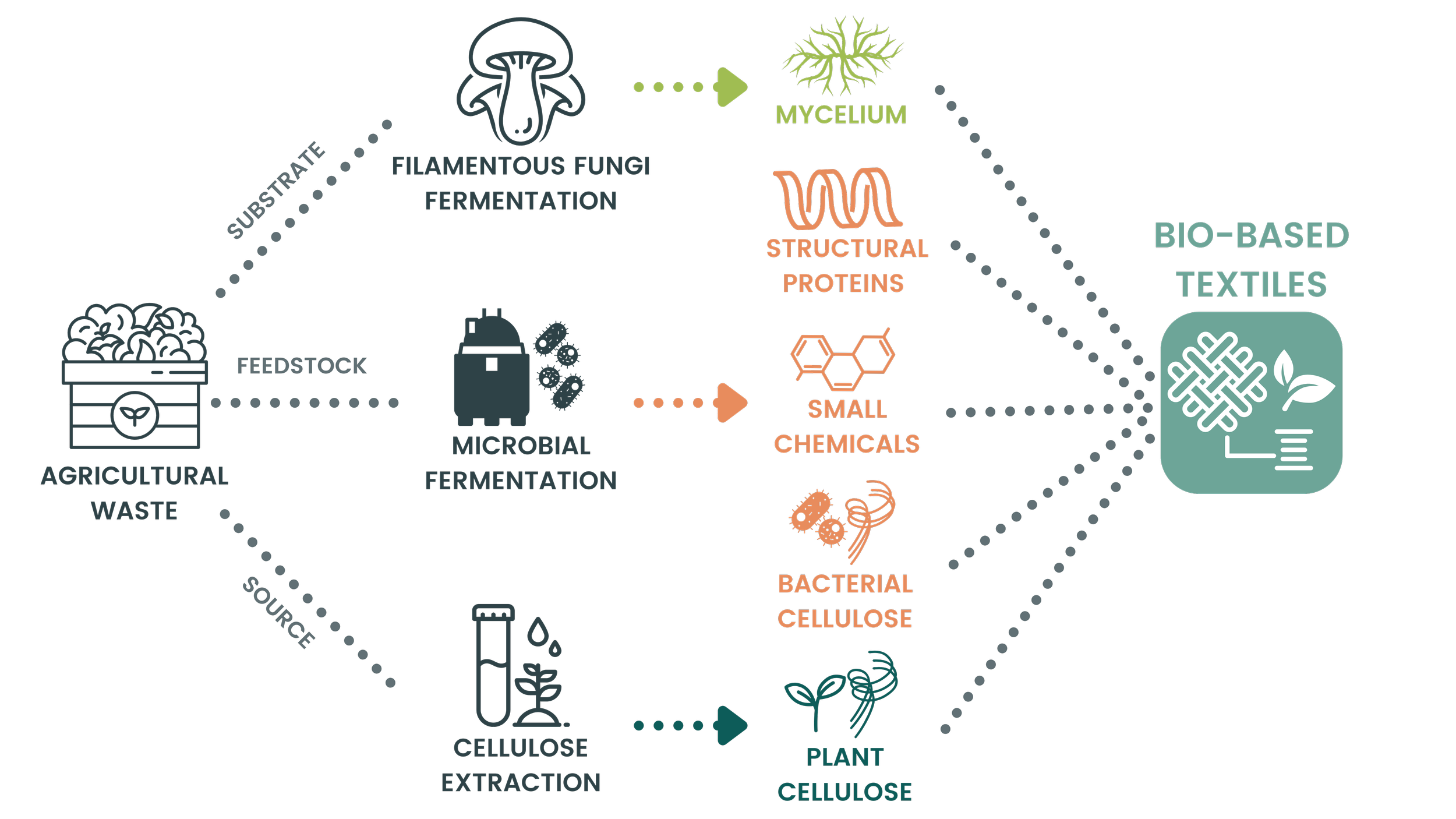

There became, however, another option. Starting in roughly the mid-2010s* (although originating in concept almost a century earlier), a boom of several startups began to look at alternative starting materials and manufacturing processes to consider creating biomimics of animal-derived materials in a more sustainable way. Some looked towards processing the cellulosic fibers from food waste into a sheet of material, similar to leather. Others looked towards chemically similar waste from the oyster mushroom industry. Still others thought to obtain cellulosic fibers from bacteria or grow, in a lab, the animal cells that natively produce the animal-derived materials. In this way, the so-called “next-gen” biomaterials either seek to use novel bioassembled materials to create replacements or they seek to use organisms themselves to recreate the mimicked material at a biochemical level.

Plant tissue, fungal mycelia, microbial cellulose, and cultured animal cells provide sources of fibers for bio-based textiles.

Creating biomaterials without using the animal of origin is similar, in concept, to creating these materials in the traditional way. If a living organism is going to assemble a material, any given manufacturer will first need to feed the living thing. Sourcing an appropriate feedstock is essential both to maintain the organism’s life but also to provide the raw material needed for the organism to create the material that will later be harvested. Once the material is harvested, it then needs to undergo post-processing to improve its stability and workability, and then the material itself can enter into any other process that incorporates it. Although bio-based textile companies may advertise different biomimicked products as their brand, the critical point that differentiates bio-based textiles is the process of bioassembly itself. And, also critically, bioassembly depends on access to a particular feedstock that may or may not also require its own processing. Therefore, the important information to examine when learning about a startup is the process by which they create their materials.

Biomaterials advertised as plant-derived attempt to access cellulose in plant tissue, whether those plants are harvested specifically for the purpose of biomaterial creation or are a product of food waste streams. Because plants are the organism doing the bioassembly, the feedstock is what plants require to grow: sunlight, sufficient soil, water, and appropriate additives to aid in their growth (e.g., fertilizer, pesticides, etc.). Plant tissue, in the form of fruit peels, skins, or other undesired waste is then chemically processed to extract cellulose fibers, the carbohydrate plants use for creating rigid structures within themselves. Plant-derived cellulose can then be bound together using small chemicals, either derived from fossil fuels or, in some cases, precision fermentation technology. A common end product from this process is plant-based alternative leather; however, the majority of companies in the bio-based textile space make use of cellulose fibers derived from these bioprocesses.

Any material advertised as using mycelium refers to the dense mat of small, individual hyphae filaments that certain fungi produce when growing. These structures are analogous to roots of plants in that the fungus uses them to access nutrients from its environment. Similar to plants, fungi reinforce their hyphae with structural carbohydrates, and accordingly, mycelia can be treated much like plant-derived cellulose. Mycelium can be harvested itself and shaped into sheets or mats once post-processed, or fungi may be grown on plant-derived cellulose meshes that both cluster and feed the growth of the fungus. In either case, feedstock appropriate to fungi needs to be accessed, but there has been work reusing industrial waste streams as a food source.

Microbe-derived materials also exist as a category of emerging biomaterials, but this category contains at least two distinct processes by which materials can be made. In some cases, precision fermentation via bioengineered microbes is used to produce small-molecule, such as monomers for producing materials otherwise derived from fossil fuels. Also, bacterial microbes can be grown purely for their tendency to produce bacterial cellulose. This compound is chemically identical to that which plants produce, but the structure, bulk properties, and chemical purity is different. As such, mats of bacterial cellulose can be produced and treated similarly to the mats of structural carbohydrates produced by other organisms but with the benefit of faster growth times associated with bacteria and well-characterized feedstocks already present in the growing field of industrial precision fermentation.

Finally, there are next-gen biomaterials produced from animal cell culture. In this case, the intent is to grow animal products (especially skin tissue, for leather) in culture, separate from a living animal, but otherwise chemically similar enough to be processed like animal materials. This process not only requires a feedstock appropriate to animal cells, but also manufacturing conditions conducive to the sensitive requirements of animal cells and a feedstock appropriate for supporting their more complex metabolisms. Nevertheless, lab-grown animal biomaterials have the promise of being bioidentical to their animal-derived counterpart which also promises a closer match to the bulk material properties of their counterpart.

Plant-derived biomass remains the most common material source companies are using for bio-based textiles in 2023.

Arguably, a key difference between the next-gen biomaterial industry and other alternative bioengineering fields is the interplay between its two distinct players: startups (often called “innovators”) and established textile companies (“brands”). Innovators constitute the companies attempting to develop new bioprocesses to produce next-gen biomaterials; brands are the established companies who make use of textiles to produce consumer goods. As such, innovators have the challenge of working to create materials that can integrate seamlessly into the industrial technology brands possess for working the materials. Brands may sometimes have their own internal innovators, and some innovators themselves work to form partnerships between several brands, providing, for example, market exclusivity for a particular new biomaterial. As such, when evaluating a company, not only must its underlying bioprocess be scrutinized, but also the feedstocks needed to produce the process and how aware a company may be that they are working in a business-to-business industry.

Currently, ~60% of the businesses in the space (out of ~130 in total) are working on creating leather substitutes. Of these, the majority use plant-derived biomass, with the other half made up of roughly equal numbers of companies using microbe-derived, mushroom, and blend biomass. The rest of the businesses are made up of companies pursuing materials similar to wool, silk, down, fur, and exotic skins. Of these, wool and silk seem to favor plant-derived biomass, down has a slight preference for recycled materials over plant-derived fibers, and fur uses blends of plant-derived fibers (and some recycled petrochemical), and exotic skins (only two companies) use animal-cell culture.

Tools and methodologies designed to measure and compare the sustainability of a production process require critical examination.

The overall aim and driver of innovation in bio-based textiles is to produce materials similar to animal-derived materials and their petrochemical mimics in a more environmentally sustainable way. “More environmentally sustainable” can mean several things, but it is generally measured as either a function of the production process used (so-called, “cradle-to-gate”) or an additional measure of how much waste remains once the product ends its use (“cradle-to-grave”). Therefore, companies and third parties will commission life-cycle analyses (LCAs) to determine the relative sustainability of any given production process for any given product. A feature of the LCA is that, depending on the quality or availability of data, as well as the baseline assumptions of the bounds of the life cycle (for example, a linear-nonrenewable, or a circular-renewable lifecycle), may produce different or seemingly contradictory results. As such, when assessing an LCA, a discerning investigator needs to understand the underlying assumptions the model makes.

Nevertheless, in an attempt to create a comparative rating of the environmental sustainability of textiles, the Sustainable Apparel Coalition (SAC) created the Higg Materials Sustainability Index (MSI); however, there were several key flaws examined and exposed in the Higg Index that ultimately stem from the difficulty of one-to-one comparisons of LCAs. These issues came to light most publicly in 2022, and the SAC since paused the use of the Higg Index pending a revision slated to be published in 2023.

This is mentioned because reporting on environmental sustainability remains one of the key open areas of innovation for both bio-based textiles and other textiles in general. Although startups will continue to innovate on how they access and process different sources of biomass to get closer and closer to matching the material properties of animal-derived and traditional textiles, environmental sustainability remains a major area of concern (even, for example, in growing cotton, where water use and pollution from pesticides and fertilizers can disrupt a local ecosystem). Research into renewable feedstocks and circular process design considerations (“cradle-to-cradle”) are equally important to bioprocess innovation, and all three may be considered ripe for future research.

*This link, here and elsewhere, references the Material Innovation Initiative group’s 2022 State of the Industry Report: Next-Gen Materials (Siu, et al. 2023).

Written by Jeremiah Johnston

Charts by Diana Garibay, Helikon Associate

Schedule a call to learn more

Helikon Consulting strives for accuracy and completeness in our reports. If we have presented information incorrectly or unintentionally omitted relevant details, please let us know by submitting a request for updates using this form.